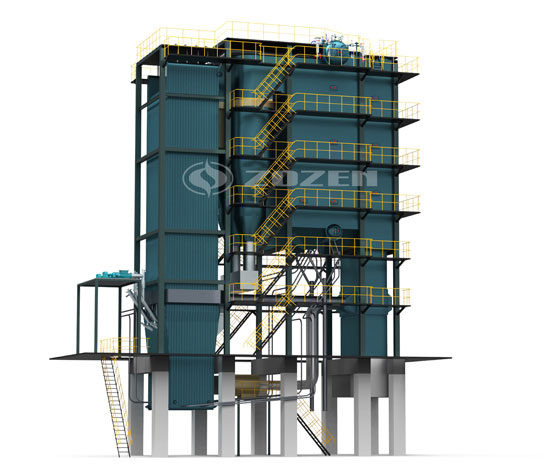

50 tph DHX circulating fluidized bed boiler project

Project boiler medium: Steam

Capacity: 35 tph, 50tph

Project site: Xinyu, Jiangxi

Equipment: DHX35-2.5-P, DHX50-2.5-P

Application area: lithium industry

Case introduction

Jiangxi Ganfeng Lithium Industry Co., Ltd. is a leading company in chinese lithium industry, specializing in R&D, production, and operation of lithium and deep-processing lithium compound products. In order to improve the production efficiency, Ganfeng Lithuum has purchased a 35 tph energy-saving DHX series circulating fluidized bed boiler in ZOZEN boiler. The furnace has a wide range of combustion adaptability.

It can not only use high-quality coal, but also use various low-grade coal, and the combustion technology is environmentally friendly.The use of large-tonnage circulating fluidized bed boilers in the lithium industry is a national development trend. The 50tph circulating fluidized bed boiler is also a medium-sized boiler suitable for the lithium industry. In 2017, Ningdu County Ganfeng Lithium Industry Co., Ltd., a subsidiary of Ganfeng Lithium, planed to invest in 17500 tons of battery-grade lithium carbonate production line projects. A 50 tph DHX series circulating fluidized bed boiler was purchased again at ZOZEN boiler. This series of boilers has a large load regulation range and fast load regulation.

Customer feedback

At present, chinese environmental protection requirements are increasingly stringent. After the ZOZEN team installed circulating fluidized bed boilers for us, the emission of helium-oxygen compounds was much lower than that of pulverized coal boiler, and high-efficiency desulfurization was directly realized during the combustion process, and the technical equipment was economically simple. The initial investment and operating costs of desulfurization are much lower than those of dry coal dust and flue gas desulfurization.