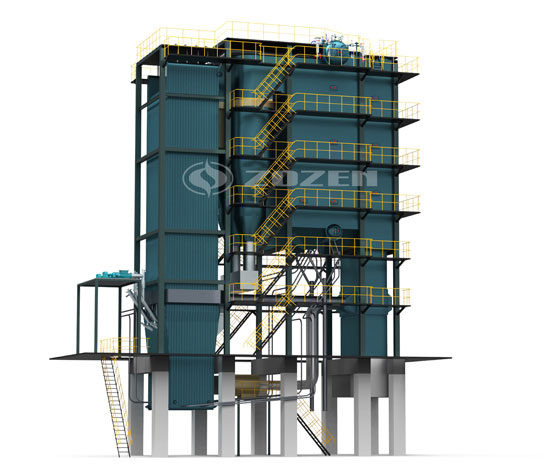

Description

YLM thermal fluid heater is square coil horizontal chain stoker assembly heater, chain stoker and heater body are transferred separately. It adapts chain stoker to realize mechanical feeding coal, mechanical venting by blower and exhaust fan, and mechanical discharging by slag machine. Fuel fall on the stoker by coal bucket during operating and burning, high temperature smoke enters furnace by passing combustion arch, after radiation heat exchange, smoke enters convection heating surface for convection heat exchange, then goes to waste heat boiler and air pre-heater, at last enters dust collector then vented into the atmosphere through chimney by exhaust fan.

Technical advantages

1. The manufacture of square coil pipe in pipe bender to pre-bend and then butt joint. No forced shaping.

2. The manufacture of serpentuator in convection area adopts serpentuator automatic production line and shaping one time

3. Square coil pipe and coil pipe all adopt argon arc welding technique and the weld line will be done 100% radiographic inspection.

4. The optimized radiation heating surface and convective heating surface, the medium flow is more reasonable, without the carrier overheat and reduce the life;

5. We have combustion arch patent, which is available for different types of coals, even the soft coal is also very easy to burn.

6. Use superior refractory brick to build inside and concave-convex panel outside and superior perlite in the middle. Keep the furnace temperature under 50℃ to make the minimization of loss.

7. Furnace adapt double close line coil, which makes heating surface is sufficient.