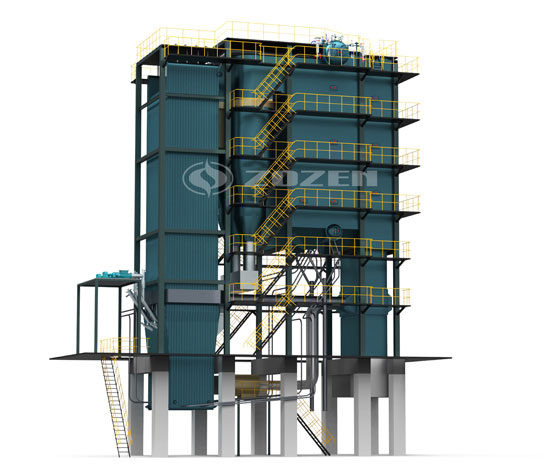

Description

WNS series horizontal internal combustion boiler is a boiler shell type 3 passes wetback oil/gas fired boiler. After fuel is being atomized by burner, flame is full of the wave furnace and transfer heat via furnace wall, this is 1st pass; the high temperature smoke is collected in reversal chamber and then enters 2nd pass which is grooved tubes bundle area; after heat convection, air temperature gradually falls and goes to front smoke box and turn to 3rd pass, which is smooth tubes bundle area, and then enters chimney passing back smoke box and exhausted to the atmosphere.

Technical advantages

1. The front and back smoke chamber plates are cut by CNC plasma cutting machine with tidy and beautiful look.

2. Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint are test by radiographic inspection.

3. Fin tube uses ND steel or stainless-steel material to avoid corrosion in the low temperature .

4. Sufficient steam storage room and heating area to generate high quality steam and high thermal power.

5. Condenser is added to recycle the waste heat of the exhausted smoke to increase feeding water’s temperature and reduce flue gas emission temperature and increase the thermal efficiency over 98% and save operating cost.