Description

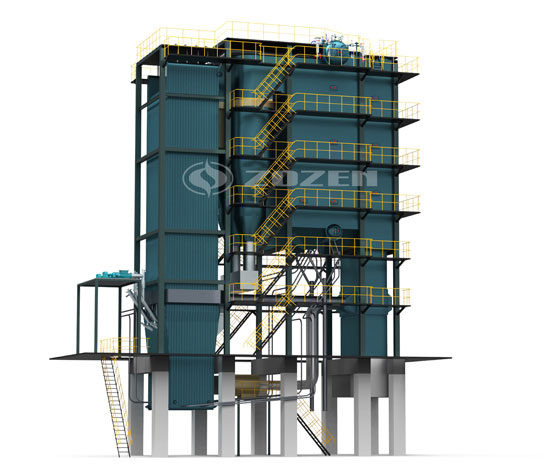

SZS Series Boiler is double drums, longitudinal arranged, "D" type chamber structure. Furnace is on right side and convection tube bundle is on the left. The body is fixed on the basement by middle and both end flexible supports and make the boiler to expand horizontally to sideways.

Around furnace is membrane water cooling tube wall. Furnace and tube bundle is totally separated by the membrane water tube cooling wall at the left side of the furnace. The back part of bundle is sparse shift structure, front part is aligned structure. Smoke from furnace outlet enters re-burning chamber, bundle area, and then from left front part enters spiral fin coil economizer and condenser, finally discharged to atmosphere through chimney.

Technical advantages

1. Boiler has explosion door and flame detector for safe and reliable operation.

2. air tightness test is done before leaving the factory to ensure no leakage of gas.

3. Combustion chamber use full membrane water cooling wall structure, pressurized firing without smoke mixture.

4. Inside of Inspection holes use high-alumina refractory and man hole cover sealing devices, it solved the high temperature of this part by using refractory brick.

5. Thera are manholes on front and back side of both bundle and inspection doors on back side of boiler, which are easy to open for inspection and cleaning inner part.

6. The key part such as material cutting, rolling, drilling are proceeded by advanced CNC machining process to reduce the assemble stress and extend boiler working lifetime.

7. flutter prevention fastener is used for high temperature part convection tube, which avoid bundle tube cracking problem.