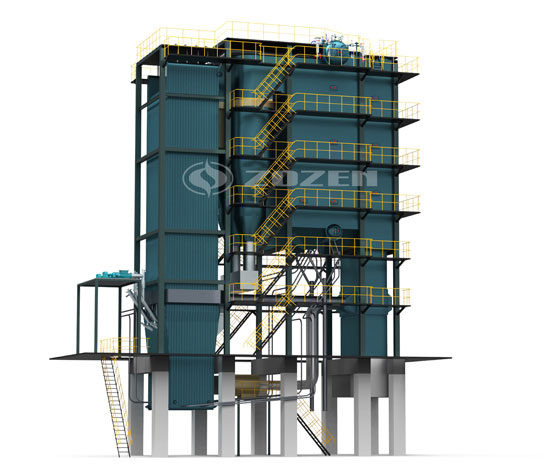

Description

SZL series vertical dual drums chain grate water pipe steam and hot water boiler, adopts quick fitting and assembly structure. The 4-6t/h boiler is of quick fitting pipe structure, exit shop after completely assembled, the boiler of 6-35t/h is composed of 2 main components. The upper assembled components is the body heat accepting part, and the lower assembled component is of combustion equipment. The former part of the boiler body is arranged an water cooling wall, the upper part of it is connected to boiler cylinder, and its lower part is connected to collective chest, so as to form a combustion room and absorb the radiated heat from the furnace. Its rear part is arranged with dense convection pipes between upper and lower boiler cylinders. The high temperature smog after combustion shall stand for twice returning flushing transversely to the heat accepting surfaces, and shall be introduced to coal saver singly arranged, and flow into duster and exhausted from chimney in the end.

Technical advantages

1. Steel pipe cutting, thread pipe pressing and convection pipe processing adopt advanced CNC process.

2. Tube flange weld adopts robot welding.

3. The chain grate panel, front and rear smoke chamber panel adopts CNC plasma cutting machine to cut orderly and beautifully. Unique structural design.

4. According to different capacity, different numbers of independent wind bins are set from front to back of the grate.

5. The spreader feeds evenly to prevent tempering.

6. We have a numerical simulations of different biomasses, we find the thermal efficiency is more than 90%.