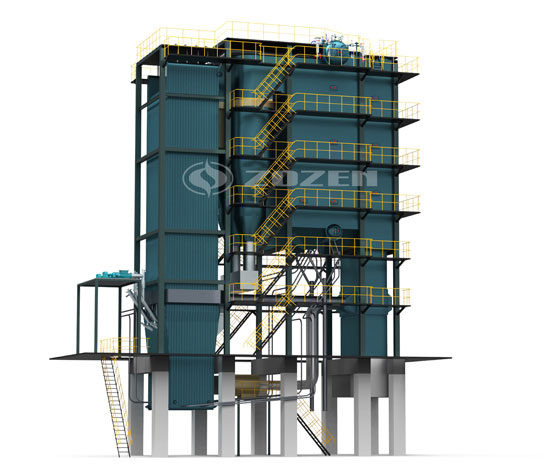

Description

DZL series package boiler is a horizontal three-pass water and fire pipe chain grate boiler, which uses medium-sized bituminous coal. The boiler body is vertical single drum, and the threaded pyrotechnic tube is arranged in the drum to form a convection heating surface, and the drum and the water walls on both sides constitute a radiation heating surface of the furnace. The combustion equipment uses light chain grate, the whole package is finished in the factory. The electric control makes the governor stepless speed regulation, the limit parameter alarm and the interlock protection.

Technical advantages

1. The key processing technologies such as steel plate blanking, circling, drum and tube plate drilling adopt advanced numerical control processing to reduce the assembly stress and prolong the service life of the boiler.

2.The use of arched tube sheets and threaded fire tube was first adopted in China to increase heat transfer and completely solve the problem of cracking of the rear tube sheet.

3. The vertical and circumferential seam welding of the boiler adopts advanced automatic submerged arc welding technology to ensure the welding quality. All vertical and circumferential welds are subjected to 100% ray detection.

4. The welding of smoke pipe and the tube plate adopts pre-expansion to eliminate the gap between the tube and tube plate, then be welded by automatic argon arc. Which effectively eliminate stress and prolong boiler life.

5. Threaded fire pipes are highly efficient heat transfer elements for many years of research by our company. After continuous optimization, the heat transfer coefficient is 1.8 times higher than that of conventional fire pipes when the selection of thread groove depth and pitch.

6. Disturbed flue gas to ensure complete combustion of volatiles.