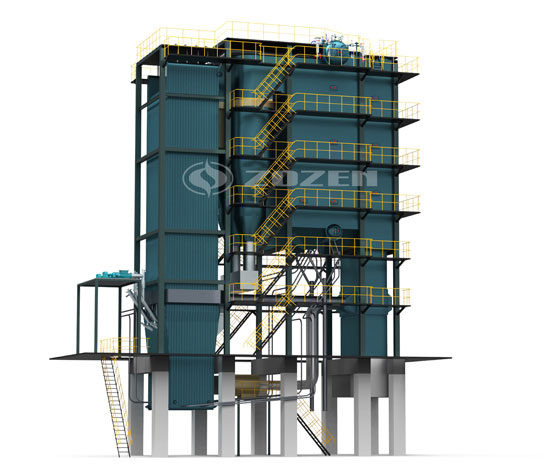

Description

Conner Tube Gas-Fired Boiler use a piping system as the frame of the whole boiler, which affords all loading of boiler, meanwhile this frame is used as falling pipe and upper/lower header. This boiler drum is external type, furnace is complete sealing membrane wall structure, convection heating surface is flag pipe. Corner tube boiler has many advantages such as compact structure, less steel material consumption and fast temperature rising speed, so it is widely used in many industries.

This boiler is in bulk structure.

Technical advantages

1. Safely water circulation: by using special water circulation system, drum is not heated, the heated water flow by single directions, when the power is shut off, water system will not be vaporized, so water circulating system is very safe.

2. Anti-knock structure: corner tube boiler is non-frame structure, its weight is afforded by membrane water call and falling pipes, and membrane water all is welded as one whole piece, it has good vibration resistance.

3. Complete sealing structure: The boiler body is all welded by the membrane water wall, it is complete sealing steel structure and avoid air leakage. The upper part of the boiler can be divided according to the railway transportation dimension requirement. The excess air coefficient at the tail part of the boiler is less than 1.2, which not only reduces the exhaust heat loss and the electric consumption of the induced fan, but also greatly reduces the environmental pollution of the boiler room.

4. Light insulation material of furnace wall: The outer wall of the corner tube boiler adapt light insulation material, 200mm thick elastic special compound silicate plate and 40mm thick slurry cover, and then reinforced with metal plate instead of brick wall structure, the insulation effect is excellent.