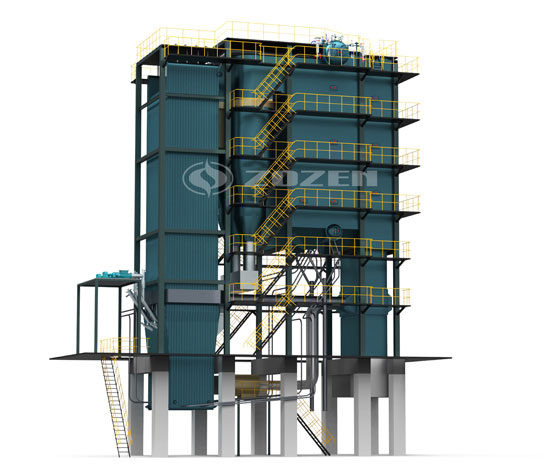

Description

SZS Series Boiler is double drums, longitudinal arranged, "D" type chamber structure. Furnace is on right side and convection tube bundle is on the left, super heater is arranged at convection tube bundle. The body is fixed on the basement by middle and both end flexible supports and make the boiler to expand horizontally to sideways. Around furnace is membrane water cooling tube wall. Furnace and tube bundle is totally separated by the membrane water tube cooling wall at the left side of the furnace. The back part of bundle is sparse shift structure, front part is aligned structure. Smoke from furnace outlet enters re-burning chamber, bundle area, and then from left front part enters spiral fin coil economizer and condenser, finally discharged to atmosphere through chimney.

Technical advantages

1. Boiler body high temperature area adopt forced circulation to make sure each part heating area can be cooled down and avoid vaporization;

2. comb plates are used as the sealing between both sides of boiler and tube bundle all use to avoid leakage of condensate and gas which is caused by refractory concrete sealing.

3. Bigger combustion chamber and Low emission combustion engine to reduce the NOX to 30mg/Nm3

4. Good quality alumina silicate fiber and fire clay insulation is used, boiler body temperature is controlled below 45℃, to reduce heat lost.

5. Combustion chamber use narrow distance tube membrane water cooling wall which has good air tightness, and reduce heat lost and increase boiler thermal efficiency.

6. Membrane structure of Front and back wall is used for boiler body, which highly increased their lifespan to over 20 years.

7. Longitudinal and girth joint adopt advanced automatic submerged-arc welding for good welding quality. All longitudinal and girth joint will have 100% radiographic inspection.