Question: How much is the cost of transforming a 4-ton coal-fired boiler into a biomass boiler?

Answer: The cost of materials is about 35,000. Manpower is not easy to calculate. The price gap between different regions is wider.

Question: How do coal-fired boilers transform biomass fuels and what are the methods?

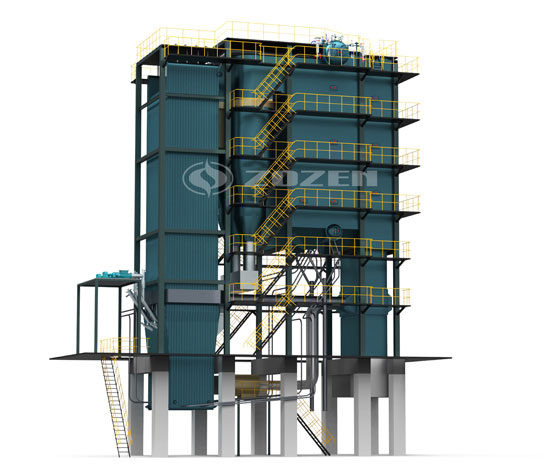

Answer: The method of reforming coal-fired boilers with biomass fuels

(1) Use the original or idle chain grate coal-fired boiler body and auxiliary equipment of the boiler: blower, induced draft fan, slag discharger, economizer, reducer, dust collector, boiler control cabinet and instrument valve, etc., to reduce the investment cost of the boiler and auxiliary equipment.

(2) The original coal hopper used for coal fuel is converted into a sealed biomass hopper, and an anti-tempering device is installed.

(3) Install a set of conveying, storing and feeding devices for biomass pellet fuel.

(4) Install a set of spiral biomass pellet fuel feeder, and open a check hole at the top of the feeding pipe connected with the closed hopper at the top of the spiral feeder, and install a stroke switch to automatically control the starting and stopping of the motor of the spiral feeder. When the screw feeder is installed, the connection between the conveying pipe and the ground conveying hopper should have a certain inclination angle. In order to save the area occupied by the boiler room and meet the process layout requirements of the boiler room design specifications, the inclination angle of the feeding pipe should be less than 60 degrees. Installation of screw feeder.

(5) Install a set of secondary air supply equipment and secondary air supply pipe on the side of the boiler. The secondary air supply pipe leads to the boiler hearth and the closed hopper to ensure sufficient oxygen for fuel combustion and complete combustion. Installation of secondary air supply equipment

(6) Problems needing attention in boiler renovation

1.The net distance of the front end of the furnace shall not be less than 3m. Because after installation of screw feeder, the distance between the ground conveying hopper and the front section of the boiler is 1.9m (taking 2t/h chain grate coal-fired steam boiler as an example). If it is less than 3m, it is not easy to operate and repair.

2. Biomass fuels should not be stored in open air, and measures should be taken to prevent rain, wind and corrosion. In addition, during the storage of biomass fuels, the temperature of fuels should be checked frequently in order to prevent spontaneous combustion caused by excessive temperature.

Q: How much steam does a ton of biomass produce in a biomass boiler?

Answer: I'll give you an estimate of how much steam can be produced under normal conditions. The calorific value of biomass is 4200/kg, and the thermal efficiency is 80%. 4200X1000X0.8 = 3360000. When a ton of biomass is put into the boiler to remove heat loss, 3360000 calories can be obtained. A ton of steam needs 600000 calories, 3360000 600000 = 5.6 tons of steam.

Question: How many particles should be burned in a day when a 4-ton biomass boiler runs 24 hours, according to 4000 cards?

Answer: 4 tons of boilers are 2.4 million calories. The general thermal efficiency of biomass boilers is 85%, 2.4 million calories/4,000 calories/85%*24 hours = 16,941 kilograms of particles per day.

Question: How to rectify a 4-ton boiler from coal-fired to biomass-fired

Answer: Our reform of the boiler mainly through the modification of grate and blast system to achieve the purpose of burning biomass.

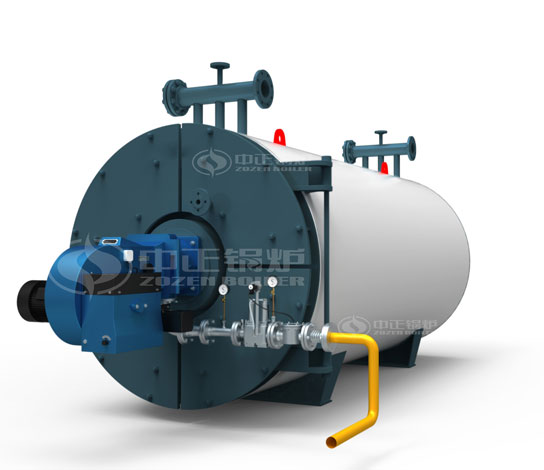

Q: What is the price of a 4 ton biomass hot water boiler?

Answer: What is the price of a 4 ton biomass hot water boiler? First of all, we need to know that the price of biomass hot water boiler consists of two parts, one is the boiler body, the other is the auxiliary equipment of the boiler. Boiler body is generally good to determine the price, the price of boiler auxiliary machine will vary greatly according to the quantity of auxiliary machine and the material quality of auxiliary machine.

Q:Is it a technical innovation to replace the original 4-ton coal-fired boiler with the 6-ton biomass-fired boiler?

Answer 1: Small capacity boilers have been replaced by large capacity boilers. In terms of production, technical renovation projects should be included.

Answer 2: Hello, it's not a technical change, it's a new boiler.

Question: How much gas will be generated by normal combustion of 2 ton and 4 ton biomass boilers?

Answer: The theoretical gas production of a 2-ton steam boiler is 2,000 kilograms of steam, and that of a 4-ton steam boiler is 4,000 kilograms per hour.

Q: How little steam can a 4-ton biomass boiler produce in an hour?

Answer: A 4-ton biomass boiler can turn 4 tons of water into steam in an hour. Although the volume of steam is larger than that of water, the weight of steam remains unchanged. It is still 4 tons.