Flue gas will be emitted during the operation of industrial boilers. At this stage, China has strict standards for the flue gas emissions of boilers, which is closely related to environmental protection. Industrial boilers with flue gas emissions that do not meet the standard cannot operate normally and need to be shut down. Only through boiler renovation or re-purchase.

The use of industrial boilers can be controlled at a very low price through transformation, and the trouble of repurchasing new boilers can also be eliminated. Zozen Boiler Factory helps everyone understand how industrial boilers have completed low-nitrogen environmental protection transformation through an example of the transformation of an enterprise's industrial boilers.

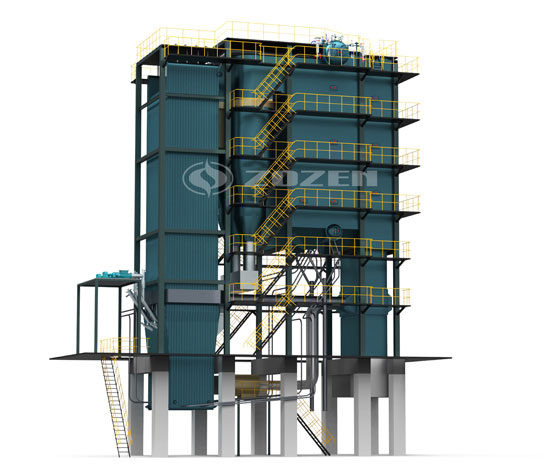

The boiler model is SHL35-2.45-AII boiler. During the operation process, the effect of the dust collector cannot reach the industrial boiler flue gas emission standard, and the emission cannot be achieved. Due to the continuous improvement of the environmental protection standards for desulfurization, denitrification and dedusting of industrial boilers, the technical reformation of desulfurization and dedusting of existing boiler dedusting equipment is required, so that the smoke and sulfur dioxide emissions in the boiler flue gas meet the relevant national environmental protection requirements.

This boiler reform follows the control requirements that meet the environmental emission standards of industrial boilers; choose mature and reliable dust removal and desulfurization processes; the operation of the dust removal and desulfurization system does not affect the operation and operation of the original production equipment, and ensure the safe and stable operation of the boiler system; management Convenient maintenance; combined with the existing plant and equipment, make full use of the original equipment and system, reasonable layout, small footprint, meet the overall system and site layout requirements; overall consideration of dust removal, desulfurization, and denitrification transformation, after the transformation must not be implemented in the future The principle of the impact of the denitrification renovation project.

After the transformation of the flue gas system and desulfurization tower system is completed, the current flue gas emissions of the boiler are: sulfur dioxide emission concentration ≤160mg / Nm³; smoke dust emission concentration ≤30mg / Nm³; flue gas Ringerman blackness is 0 -Level 1. When the dust concentration at the inlet of the dust collector is ≥4000mg / Nm³; when the concentration of sulfur dioxide is ≥3000mg / Nm³, the dust removal efficiency is ≥99.5% and the desulfurization efficiency is ≥95%.

After the transformation of the industrial boiler, the environmental protection department must also apply to the environmental protection department for acceptance monitoring and evaluation according to the acceptance level of the environmental protection project.