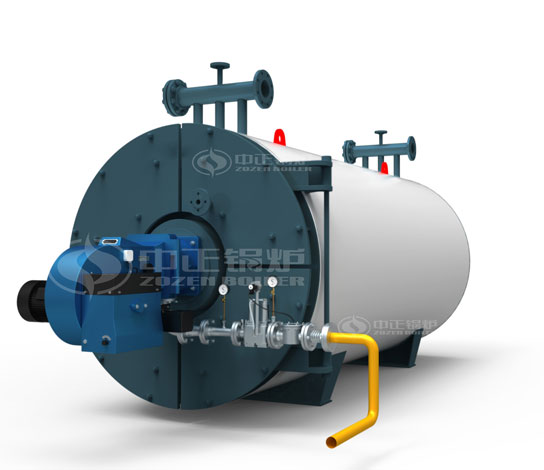

The working pressure of industrial horizontal boiler nameplate rated steam pressure should be greater than the sum required for the production of steam piping resistance and working pressure. Do not ignore the steam pipe resistance.

1.Industrial Boiler working pressure

Gas boiler nameplate rated steam pressure should be greater than the sum required for the production of steam piping resistance and working pressure. Do not ignore the steam pipe resistance, because of its vapor pressure rated saturated steam temperature is higher.

2.Industrial boiler heating area

Compare gas boiler heating area ( heat transfer area ) is an important parameters. Because heating boilers generally contribute a large area , strong overload capacity , whereas the output is small. Same boiler capacity , heating area is relatively large , relatively low exhaust gas temperature, boiler efficiency is relatively high , the heat generated by the burning fuel more fully utilized, fuel consumption is low .

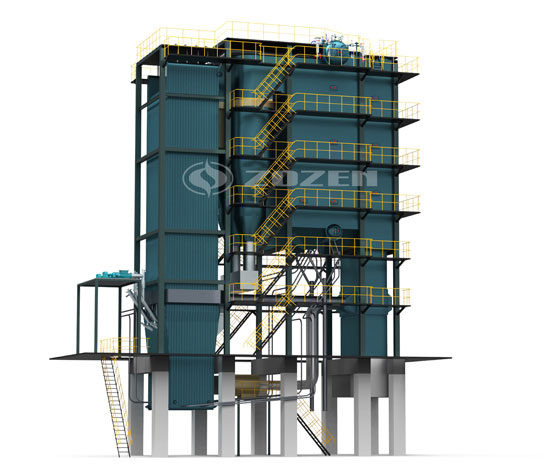

3. Industrial boiler furnace structure comparison

Boiler furnace diameter compare is one of an important parameters. Many domestic furnaces carbon deposition and smoke tube have ash soot deposition, even the black smoke out from boiler after running some days. One of the main reasons is the small furnace diameter, atomized oil particles injected into the furnace burning on the wall due to the high temperature carbonization without burn. ZG boiler provide steam boiler, hot water boiler, power station boiler etc. The boiler furnace diameter and length can fully meet the requirements of combustion with sufficient space.

4. Furnace of industrial horizontal boiler

Furnace is manufactured by the industrial boiler manufacturer. Quality furnace is mainly determined by two aspects , namely the design and manufacture. Mainly in the construction and arrangement of the boiler heating surface temperature and other parts of the selection, especially furnace outlet temperature control and other aspects of the structure of the furnace.