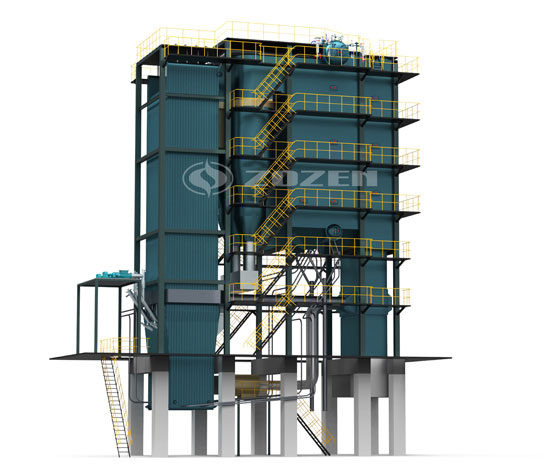

The elimination of coal-fired boilers, especially small coal-fired boilers, is imperative. At present, various provinces and municipalities have different regulation policies for coal-fired boilers under 10 tons, 20 tons and 35 tons. But the trend of transition from small boiler to large boiler is irreversible. The so-called energy-saving and efficient coal-fired boilers, such as large circulating fluidized bed boilers and large corner tube boilers, are highly efficient equipment implemented by the state, with low emission, high efficiency and mature technology. Even today's gas-fired boilers are not comparable. It is also because of the advanced technology of coal-fired boilers that its technology is gradually used in biomass boilers, waste heat boilers and other representative types of energy-saving and emission reduction era, so that biomass boilers go abroad to sell to many countries in the Americas, but also let waste heat boilers cover the circulating fluidized bed technology, to re-strengthen China's circular economy.

Coal-fired boilers will still occupy an absolute position for a considerable period of time now and in the future. The coal-fired boilers eliminated in public opinion are small, highly polluting old equipment. It can be seen from the list promoted by the National Development and Reform Commission that medium and large-scale high-efficiency and low-emission coal-fired boilers are still the main force of promotion. Although the state bans small boilers, there is still a huge market for small environmentally friendly coal-fired boilers in export. Today we will analyse the daily coal consumption of the boiler, the monthly coal consumption and the annual fuel cost of the coal-fired boiler, and provide some reference for the customer's investment budget of the boiler.

1. Fuel Consumption Calculation of Coal-fired Boilers

Coal consumption of coal-fired boilers = heat required by boilers / calorific value of coal / thermal efficiency of boilers

For example, a ton of coal-fired boilers require 600,000 calories per hour. Take the coal fuel with the lowest calorific value of 5500 kcal/kg as an example. Assuming that the thermal efficiency of the boiler is generally about 80% (CFB furnace can achieve combustion efficiency of about 92%, which is comparable to the national standard efficiency of gas-fired boilers), the coal consumption per hour of a ton of coal-fired boilers is 600,000 kcal/h 5500 kcal/kg 80%=136 kg/h.

It can be seen that how much fuel a coal-fired boiler consumes per hour per day depends on many factors. If the selected fuel has high calorific value and high boiler efficiency, the fuel consumption of the boiler will certainly be low, otherwise the fuel cost of the boiler operation will be increased. In addition, the more complex the furnace structure, the more factors affecting fuel consumption.

2. Reference Table of 1-hour Coal Consumption for Common Tonnage Coal-fired Boilers

| Coal consumption per hour of 1 ton coal-fired boiler is 136 kg/h |

Coal consumption per hour of 2 ton coal-fired boiler is 272 kg/h |

| Small 4-ton coal-fired boilers consume 544 kg/h of coal per hour |

5-ton coal-fired boilers consume 680 kg/h of coal per hour |

| Coal consumption per hour of 6 ton fast-loading chain coal-fired furnace is 816 kg/h |

1 hour coal consumption of 8 ton coal-fired boiler 1088 kg/h |

| 1 hour coal consumption of 10 ton chain grate coal-fired boiler is 1360 kg/h |

1 hour coal consumption of 12 ton coal-fired boilers is 1632 kg/h |

| 1 hour coal consumption of 15 ton coal-fired boilers is 2040 kg/h |

One hour coal consumption of 20 ton chain coal-fired boiler is 2720 kg/h |

| Coal consumption per hour of a 25-ton high-efficiency coal-fired boiler is 3400 kg/h |

30ton fluidized bed coal-fired boiler consumes 4080kg/h of coal in one hour |

| Coal consumption per hour for 35 ton coal-fired boilers is 4760 kg/h |

40-ton coal-fired power generation boiler consumes 5440 kg/h of coal in one hour |

| Coal consumption per hour for 45 ton fluidized bed coal-fired boilers is 6120 kg/h |

Coal consumption of 50 ton CFB boiler in one hour is 6 800 kg/h |

| Coal consumption per hour of 55 ton CFB coal-fired boiler is 7480 kg/h |

One hour coal consumption of 60 ton large coal-fired steam boiler is 8160 kg/h |

| Coal consumption per hour for 65 ton coal-fired boilers is 8840 kg/h |

1 hour coal consumption of 75 ton fluidized bed coal-fired boiler is 10200 kg/h |

| Coal consumption per hour of 90 ton fluidized bed coal-fired boilers is 12 240 kg/h |

One hour coal consumption of 100 ton coal-fired boiler is 13600 kg/h |

| Coal consumption per hour for 110 ton coal-fired boilers is 14960 kg/h |

1 hour coal consumption of 130 ton circulating fluidized bed boiler is 17680 kg/h |

| Coal consumption per hour of 150 ton coal-fired boilers is 20400 kg/h |

Coal consumption per hour of 160 ton Corner-Tube coal-fired boilers is 21760 kg/h |

| One hour coal consumption of 240 ton coal-fired boiler is 32640 kg/h |

Coal consumption per hour of 280 tons CFB coal-fired boiler is 38080 kg/h |

3. Examples of fuel consumption in high-efficiency coal-fired boilers:

(1) 75t/h Medium Temperature and Medium Pressure Coal-fired Power Plant Boiler in Chifeng, Inner Mongolia

The measured thermal efficiency is 91.86%. According to the national standard limit value, the standard coal can be saved by 9.65%, and by the national standard target value, the standard coal can be saved by 3.12%. The corresponding boilers can save 4920 tons (standard coal) per year and 1480 tons (standard coal) per year by running 5700 hours per year. According to the calculation of 300 yuan/ton (standard coal), the corresponding boilers can save 1.48 million yuan/year and 450,000 yuan/year respectively. The fuel cost is greatly saved and the coal saving effect is remarkable.

(2) 160-ton large-scale circulating fluidized bed centralized heating hot water boiler in Harbin, Heilongjiang Province (116mw)

The design efficiency of the boiler is 90.12%. The measured thermal efficiency is 91.98%, 8.98% higher than the national standard limit value and 2.98% higher than the national standard target value. Calculated by 180 days of operation in Harbin every year, each boiler can save standard coal: 37.999 * 12280/(7000 * 4.1868) * 1/83% - 1/91.98% * 24 * 180 = 8090.6 tons (standard coal) / year. According to the annual production of 5 units, the CFB boiler manufacturer can save 40 453 tons (standard coal) per year for the country.

4. Reference Table for Minimum Calorific Value of Fuel for Other Coal-fired Boilers:

| Calorific value of coke fuel: 25.12-29.308MJ/kg |

Calorific value of anthracite fuel:25.12-32.65MJ/kg |

| Calorific value of bituminous coal fuel:20.93-33.50MJ/kg |

Calorific value of lignite fuel:8.38-16.76MJ/kg |

| Peat fuel calorific value:10.87-12.57MJ/kg |

Calorific value of standard coal fuel:29.308MJ/kg |

Generally speaking, the common problems of customers, such as the coal consumption of boilers and the operation cost of coal-fired boilers, belong to the estimation. The same customer needs do not exist. Therefore, whether the design parameters or the actual operation of the boiler will be more or less different. Therefore, if you want to know more details, please consult us directly online, so as to dispel your doubts as soon as possible.